- View Mobile Number

info@pressroomautomation.net

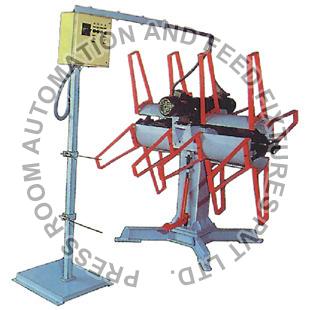

Horizontal Decoilers

Leading Manufacturers, Exporters and Wholesaler of Automatic Strip Guide Horizontal Decoiler, Double Head Motorized Decoiler, Economical Motorized Decoiler, Horizontal Decoiler Centering Device, Horizontal Decoiler Inline Straightener, Horizontal Decoiler Sliding Device and Scrap Decoiler Pneumatic Feeder from Thane.

| Business Type | Manufacturer, Exporter, Supplier |

| Condition | New |

| Driven Type | Electric |

| Usage/Application | Industrial |

| Material | Material |

| Grade | Automatic |

| Power Source | Electric Motor |

| Delivery Time | Ready Stock |

Strip Guide Consists of Following Features

- Entry & Exit Roller Support System for Width 150 mm.

- Rugged Base in welded steel for mounting various strip guide component along with lifting hooks.

- Entry Width Guide Roller with Back Support Arrangement. Entry Width Guide can be adjusted via Clamping Levers.

- Emergency Stop for Press via Antenna Rod.

- Emergency Stop for Decoiler via Bottom Plate.

- Entry & Exit Roller Support, Ultransonic Sensor, Antenna Rod are all mounted on Aluminum Frame.

- Control Panel consists A. C. Variable high frequency drive for total automation speed variation is done via Ultransonic Sensor in Auto Cycle depending on the distance of the loop. Switches like Manual/Auto, Start/Stop/Inch, Indicator Light On/Off, Pod for Speed Variation are provided.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Number Of Flower | Double Head Decoiler |

| Condition | New |

| Automatic Grade | Fully Automatic |

| Driven | Electric |

We make available Double Head Decoiler with feeding speed of 15m/min. We properly package our products using premium supplies and ultramodern technologies to make sure they endure shipping, handling, mechanical damages etc. We provide customized packaging solutions. We have a team of expert quality analysts that stringently checks each and every stage for ensuring quality products at buyer's end.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Number Of Flower | Motorized Decoiler |

| Condition | New |

| Automatic Grade | Fully Automatic |

| Driven Type | Electric |

These Economical Decoilers are fitted with a motor of greater horse power. As a trusted name, we make use of only premium packaging material to pack the products in order to ensure their complete safety during transit. Moreover, our packaging experts strictly check the same. We are associated with renowned transportation providers to ensure delivery of consignments is carried out without a glitch and in a timely manner.

| Business Type | Manufacturer, Exporter, Supplier |

| Condition | New |

| Finishing | Color Coated |

| Production Capacity | 1 Ton |

| Model | HMD-1 |

| Decoiling Speed | 36 RPM |

| Item Code | HMD-1-CD |

| Business Type | Manufacturer, Exporter, Supplier |

| Specialities | Rust Proof, Long Life, High Performance, Easy To Operate |

| Power Consumption | 2 Kw |

| No Of Roll | 9 Nos |

| Model Number | S-150-40-9 |

| Max Line Speed M Per Min | 15 MPM |

| Max Sheet Width | 150 mm |

| Delivery Time | Ready Stock |

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Application | Industrial |

| Feature | Auto Controller, Durable, High Performance, Stable Performance |

| Condition | New |

| Decoiling Speed | 36 RPM |

| Height Of Pallets | 150 mm |

| Power Consumption | 2 Kw |

| Item CodeHMD-1-SD | HMD-1-SD |

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Material | Mild Steel |

| Driven Type | Pneumatic |

| Operating Type | Automatic |

| Finishing | Polished |

| Usage | Industrial |

| Specialities | Superior Performance, Rust Proof, Durable, Easy Maintenance, Easy To Operate |

We have a good rapport with the leading e-commerce merchants who work for us and assure safe and secure transaction of money. Also, we facilitate our clients to make a transaction in both online and offline modes. In our well-constructed warehouse, we store the entire lot under safe conditions and away from various damaging factors such as direct sunlight, moisture, dust, rain, and others.

Features :

- Precisely engineered

- High operational fluency

- Reliable operation

Other Details:

- Tension winding arrangement by a set of rollers for tight winding.

- Electro Magnetic / Pneumatic Brakes.

- Coil Hold-down (Hydraulic / Pneumatic) for Springy materials.

- Jaw Expansion by Hydraulics.

- Coilers with Shafting & Key to load Bobbin.

- Special Purpose Winding Machine.

- Centrally Expandable Jaws.

- All Jaws have fully covered drum for best stability.

- Pneumatically operated hold-down with a potentiometer for speed variation & holding the coil with varying pressure with hand-lever.

- Mandrel rotating on bearings.

- Precision Tension Coiler & Winders for Strip Casting & Rolling Mills

- The Spindle would be driven by D.C. Variable Drive with gear-reducer & brake mechanism. D.C. Drive is in constant tension.

- Speed reduces automatically with diameter build-up for tight winding.

The Control Panel would have following standard parameters:

- Forward / Reverse Selector.

- Start / Stop Button.

- Emergency Shut Off & Hold-down.

- Speed / Tension Selector.

- Inbuilt Transformer.

- Potentiometer to set the Tension manually.

- The hand-lever operation for low tension in starting high tension in working.