- View Mobile Number

info@pressroomautomation.net

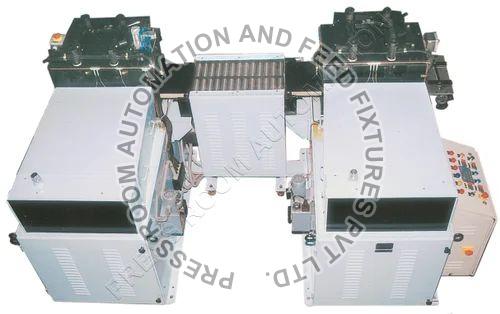

Component Levellers

Leading Manufacturers, Exporters and Wholesaler of Automatic PLC Controlled Part Component Leveller, Mild Steel Twin Component Leveller and Single Component Leveller from Thane.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Application | Industrial |

| Color | White |

| Condition | New |

| Automatic Grade | Fully Automatic |

| Material | Mild Steel |

Automatic PLC Controlled Part Leveller is with following additional features which can be pre-programmed via PLC.

- Adjustment of Straightening Rolls via Servo / A.C. Motor & Drive.

- 10-30 Pats Setting Parameters can be Stored for Quick Retrieval in Future.

- Accuracy of Roll Positioning in Range of 50 Microns.

- Entire Operating Setting by Unskilled Operator, Once pre-programed.

- Possibility of Two Three Program for Same Part due to variation of the Input Parameters like Hardness etc.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Application | Industrial |

| Color | White |

| Condition | New |

| Automatic Grade | Fully Automatic |

| Material | Mild Steel |

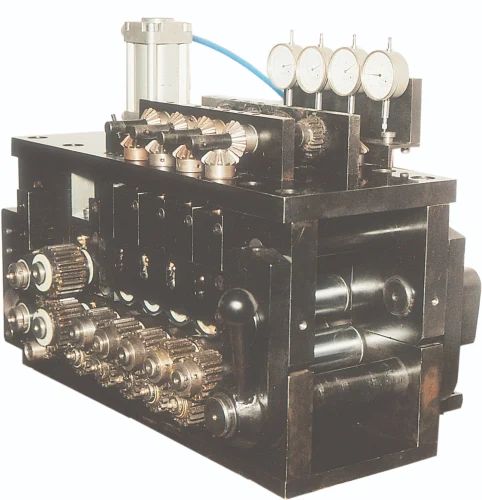

Application of parts Levelling

- Stampings

- Motor laminations

- Clutch plates

- Brake plates

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Component Leveller |

| Application | Industrial |

| Power Source | Electric |

| Automation Grade | Fully Automatic |

| Usage/Application | Industrial |

| Material | Stainless Steel |

Application of parts Levelling

- Stampings

- Motor laminations

- Coil laminations

- Control panels

- Furniture panels

- Saw blade blanks

- Clutch plates

- Microfilm spools

- Brake plates

- Bi-metal Bearings

- Computer parts

- CNC Turret punch parts.

Standard Features:

- Four-high design.

- Manually adjustable back-up rolls

- Small work rolls, hardened/ground/polished

- All Straightening rolls are Powered.

- Integral universal geared drive.

- Dial gauge roll position indicator..

- Oil bath gear case, sealed roll bearings,

- positive lubrication.

- Bolted rugged main frame in one torque resisting assembly.

- Main drive motor for 440 V, 3 ph, 50 cycle.

- “Run, Jog-Reverse, Stop” controls, Fusible disconnect..

- Automatic central lubrication of work roll bearings.

- Adjustable side guide.

- Straightening accuracy+/- 0.01 to 0.05 is achieved

- Depending on input component conditions, Raw material & hardness, roll setting, thickness variation of components.

- 17/19/21 Straightening rolls.

- Straightening roll diameter from 8 mm to 200 mm to cover a wide range of jobs.

Optional Features:

- Five or six high configuration for one or two side special polished sheet stock, in place of four-high

- Chrome plated work rolls.

- Base for larger pass line

- Slant base for press coil feed operations.

- Variable speed drive and controls.

- Loop control system.

- Powered work roll positioning in place of manual.

- Remote work roll position indicators.

- Cascade rolls at entry or exit.

- Powered pinch rolls.

- Special features on request.

- Motorised adjustment of rolls with digital display.

- 25/31 Straightening rolls.

- CNC Controlled levellers offered.